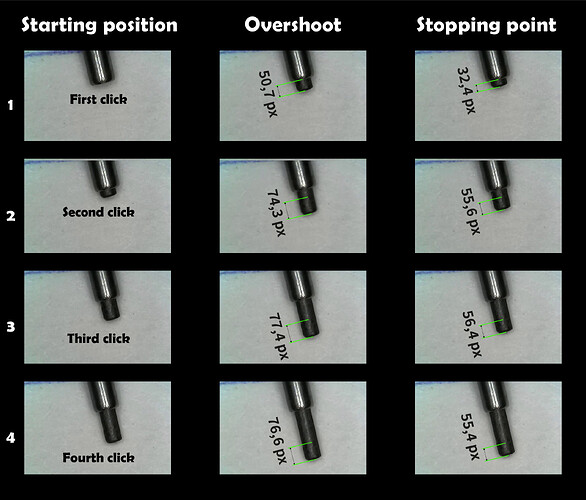

Following the article clarifying the notions of “precision” and “accuracy”, I filmed four consecutive clicks of the push button on a fairly new Pentel PG5‑AD that operates as intended.

The lead does not move quite as one might expect, from its starting position directly to its stopping point. The motion unfolds in two phases: first, a forward push that works against the spring and retention rubber, with a noticeable overshoot beyond the 0.5 mm target; then, a retraction as the chuck settles back into the ring that serves as its receptacle. The lead ultimately stabilizes close to the desired position, about 0.5 mm out.

The purpose of this demonstration is not to obtain precise measurements or to evaluate the PG5, but to highlight certain variations in motion, particularly the spread that represents the “precision” described in the previous article. I did not bother to calibrate my camera, and I do not know exactly what one pixel corresponds to in real distance, but by eye it seems to be close to one hundredth of a millimeter. In other words, fifty pixels roughly equal 0.5 mm, give or take a few pixels.

It can be seen that the first click does not advance the lead completely. This may be because I initially pushed the lead in so that it would sit flush with the fixed sleeve, but despite appearances it might have been slightly deeper than intended. Or perhaps this is simply what always happens, as the spring or the retaining rubber compresses. I will leave it to others to determine the exact cause. What is certain is that after the first click, this effect no longer plays a role, allowing us to observe subtle variations in the apex position, from 74.3 px to 77.4 px, with an intermediate distance of 76.6 px in between. The average is 76.1 px when excluding the initial push, and the difference between the maximum and minimum values is 3.1 px.

To obtain true precision, a much larger number of measurements would be required. For our purpose here, however, we can approximate it as roughly 3.1 px divided by two, or about 1.55 px. Applying the same approach to the stopping position gives 55.8 px ±0.5 px. If the intended specification is 0.5 mm (approximately 50 px), we obtain an accuracy of 0.058 mm and a precision of ±0.005 mm. These figures were, of course, obtained in a way that would make any proper metrologist raise an eyebrow, yet they remain impressive enough to please any devoted mechanical‑pencil enthusiast.

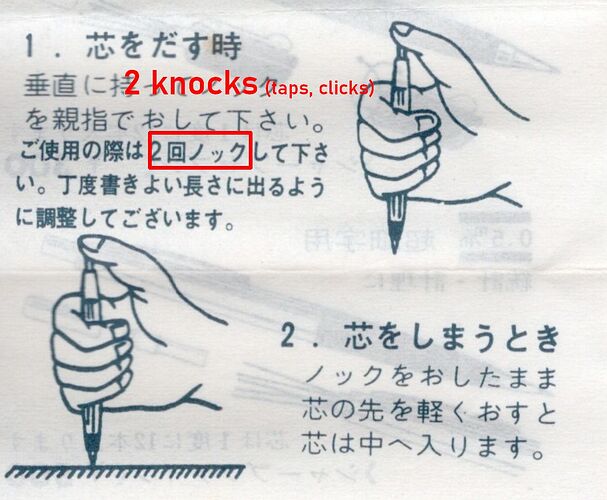

While most reviewers estimate the average lead increment by clicking ten times and dividing the distance by ten, it should be noted that extending that much lead goes well beyond what the manufacturer advises. As far as I know, for example, Pentel has always recommended pressing no more than twice to extend the lead. We can safely assume that the engineers designed the mechanism, the sleeve, and the lead itself to withstand the forces involved under those specific conditions. Ideally, to measure the true accuracy and precision of lead advancement, the test should be performed using exactly two presses—no more, no less.

That said, I don’t think it’s worth the bother. The average lead increment is sufficient for us to have an idea which pencils are better built. There is no need to equip oneself with ultra-precise measuring instruments, or to hire a metrology lab. A micrometer or a caliper is already a bit too much.