Accuracy is how close a measured value is to the desired or target value. In most cases, the target value is the true value we want to find. We measure things to discover what is actually the case. But in product design and manufacturing, such as when making a mechanical pencil, the desired value is a specification—a set goal, an intended outcome. Because of small variations in materials and processes, real-world results rarely match that value exactly.

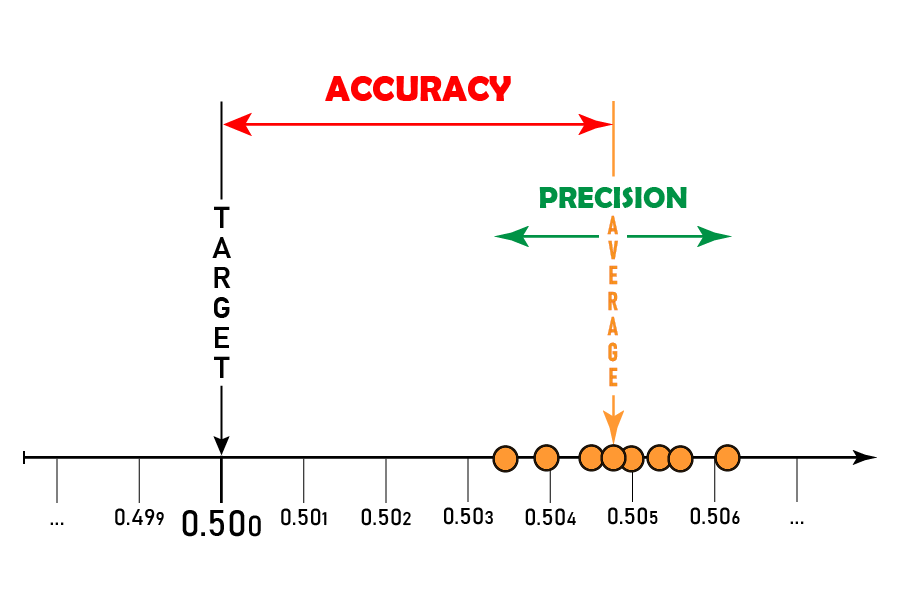

For example, if a pencil is designed so that each press of the mechanism advances the lead by 0.5 mm, the desired value is 0.5 mm. A pencil that advances the lead by an average of 0.53 mm is more accurate than one that advances it by 0.45 mm, even though the second dispenses a smaller amount, which might seem in everyday language more “precise.”

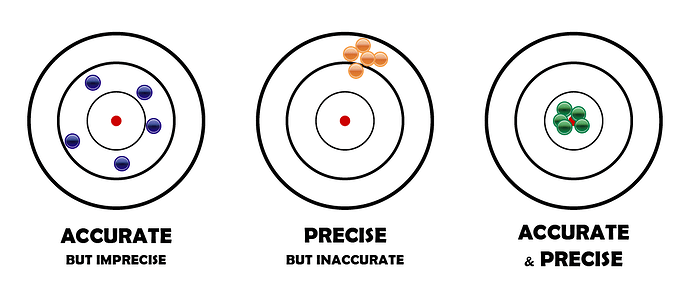

Precision, however, means something different. While accuracy describes how close a measurement is to the true or target value, precision describes how close repeated measurements are to one another.

If a pencil always advances the lead slightly too much but by the same amount each time, it is precise but inaccurate—it has a stable mechanism that only needs adjustment. Another pencil might sometimes advance the lead exactly as intended but often by varying amounts, sometimes too much and sometimes too little. That pencil is accurate on average but not precise, since its mechanism produces inconsistent results. The cause could be something like a worn retention rubber in the tip that allows the lead to slip, or a chuck that fails to return to the same position after each press.

In many mechanical pencil reviews, it is common to press the button ten times, measure the total lead extension with a caliper, divide the result by ten, and call that number “the precision” of the pencil. But this average is neither its precision nor exactly its accuracy. Dividing by ten removes the variation between individual presses—the spread—which defines precision. What remains is only an average increment. From that, we could estimate accuracy, but only if we know the manufacturer’s specification.

In an interview with a Pentel representative (sorry, I can’t find it), it was mentioned that since the 1960s, Pentel’s standard has been a 0.5 mm lead advance. We may assume this applies to 0.5 mm leads, while smaller leads (such as 0.2 mm) and larger ones (like 1.3 mm) likely use different standards. If we take 0.5 mm as our best estimate of the target value, we can subtract that from the measured average and report the absolute difference as the inferred accuracy.

Using the term “precision” instead of “accuracy” in this context is no great sin. The meaning remains clear in casual use. But it would be more accurate to describe such averaged measurements as “Lead Advance per Click” or “Average Lead Increment,” since these terms better capture what is actually being measured. These quantities should always be expressed with appropriate units, such as “mm per push” or an equivalent notation.

In summary, accuracy means hitting the correct value, while precision is about hitting the same spot repeatedly—regardless of correctness.