That seems correct to me in every respect, though I would expect pencils that use other, more premium materials to last longer than that. I also was not aware that later iterations of the TK-matic had plastic chucks. The three I have (Al, green, and black) seem to be first gen.

similar images here.

Well, clearly for me there’s no performance difference. I don’t experience any lead slippage. Maybe I have an early model with brass chuck. I’m not going to disassemble it to find out, as the process can often result in an unusable pencil.

I have one mid-tier mechanical pencil with a plastic chuck that I had to clean due to lead slippage. I’d been using a soft lead which contributed to that. But after the cleaning, it was fine. I’ve never experienced that with brass chuck pencils using soft lead. If anything, what tends to happen is lead dust build-up coats the channel and possibly the chuck, making lead advancement difficult. And then I have to clean it out with metal wire.

Outside of abuse (including things like lab exposure to corrosive chemical vapors) I’ve yet to ever encounter any complete mechanical failure of plastic chucks in a typical pencil. And regarding slippage, I’ve run into cases, albeit infrequently, where it was variations in the diameter of the lead I was using. A .01mm variation can be enough to cause slippage if the bore is right at the margin. I haven’t checked many manufacturers but I do recall that Pentel hi-polymer lead is usually somewhere between .06mm and .08mm larger in diameter than the official size, at least for .5mm and up.

Automatic designs are a lot more complex, of course, and that just seems like the wrong place to me to be trying to economize.

Hey Linus, didn’t you find the H-200x in a PILOT 2004 catalog? Looks like your notation here is still showing them discontinued in 1996.

It is the H-300x that appears in the catalogs for 2004, also for 98,02,03

Ah… yes, sorry. I didn’t zoom in close enough and… completely neglected to look at the model number, HHP-300S.

So basically from all the PILOT catalogs you’ve obtained or seen, the H-2005 and H-2003 are deleted from all catalogs following 1998?

The HH-200K (H-2005) is far more abundant on the marketplace, but then… 26 years vs. 14 years, means the HHP-300S (H-3005) was out for half the time. Unfortunately we don’t have production numbers. A ¥3000 item may be made in less quantity than a ¥2000 item, simply out of expectation that fewer will be sold.

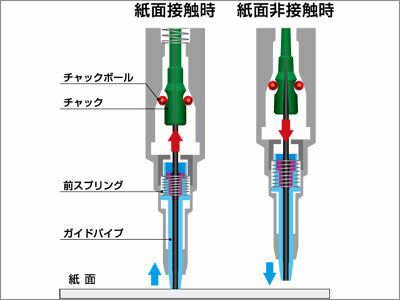

It’s quite late reply, but we should think between “fully automatic” vs “automatic”. It’s quite different. In Korea, usually said “Full-automatic” vs “semi-automatic”. “Full-automatic” should refill the lead automatically, and usually doesn’t have knob. Ex) sakura ATS-3000, Pilot Automac E, E500, Pentel QX, Staedtler 777 75. Semi-automatic is general automatic. ex) orenznero S30 automac dive etc.

As I know, pilot was just fountain pen company.

As a fountain pen company, Pilot produced a pencil called “H-5005” to boast that they had the technology to produce mechanical pencils.

So, H-5005 was their first automatic pencil.

You have some evidence of documentation that shows the H-5005 came out before the PILOT Automatic or Automac E? Because:

e, Automatic (05):83’12~(after 88) ?; (03):85~?

f, H-5005 93~?

g, Automac E 88’11~?

h, Automac E500 90~(after 02) ?

Oops. I made a mistake… I mean automatic 0.5 (HAT-3). I said this with the intention that full-automatic was developed before semi-automatic.

You are right. I made a mistake. LOL

Sorry for reviving an old thread, does anyone know which parts (grip/body/internals) can be swapped between the h-100x, 200x, 300x and the Automac? The reason I’m asking is because I’m thinking of getting a (relatively) cheap cracked h-200x and either replacing the cracked body of the h-200x with the metal rear section from the Automac or using the fancy etched grip on the Automac. Obviously this wouldn’t be collectable (and just the thought will be painful to many in this forum, please accept my apologies if you fall in this category) but if possible it would make a great looking user.

From what I understand, nothing from that series is compatible with the new Automac. The other Hi-mecha pencils were produced so early on and the last Automac version was completely tooled independently (nothing inherited from the Hi-mecha series, not even the old Automatic).

Note that the H-100x body is technically compatible with the H-200x and H-300x, but… it lacks the same body end metal collar that surrounds the eraser cap cover (plunger). But if you’re only about making it a user and not concerned with aesthetic details, it’s a possibility.

Lastly, if the body crack isn’t too bad you could try to stabilize it with glue and sand it down a bit. Or… wrap some black grip tape around it to combat the screw thread stresses.

If somehow achieved, that would be one beast of a Pilot .

Obviously I’m a bit disappointed to hear that, the internals seemed so similar in pictures… I’ll keep your H-100x suggestion in mind if I come across suitale candidates, but it wouldn’t have the same appeal as an all-metal-clad h-200x.

Replacing the plastic barrel of the 200X or 300X series with a stainless barrel would be really fantastic. I am surprised this is not a more common mod among vintage collectors.

Automac has a plastic barrel, so it could not help the cause even if it fit the 200X or 300X.

I’m pretty sure that the barrel of the Automac is metal, probably aluminium (on the black version the wear on the rear threads shows a silver colour underneath). There is a plastic insert though, which serves as guide/catch for the double knock mechanism. Come to think of it, all the plastic parts seem to be related to the double knock mechanism, while the lead advance and the outer parts are made of metal.

Hmm. Perhaps it is metal. Always feels like plastic to me. Happy to be wrong on this.

I just saw the explanations by @tfhs and I find them super interesting. Thank you very much for the valuable insights into the industry!

I completely agree with the analysis. Plastic has lots of very good mechanical properties, one important one for complex mechanical pencils it’s that it is self lubricating, so there’s no need to use oils. That’s the whole reason why they were able to build the dive so cheaply, since they can just throw a bunch of gears inside a case and not worry about having to change oils.

It would be nice to have a metal ball chuck made of metal with the possibility of servicing it. That would make repairing pencils like the orenz nero easier. Actually the orenz nero is a good example of why metal ball chucks are not ideal: that pencil is famous for lead slippage and there’s no good way to fix it as an end user, and the 3300 yen price is necessary to make it commercially viable.

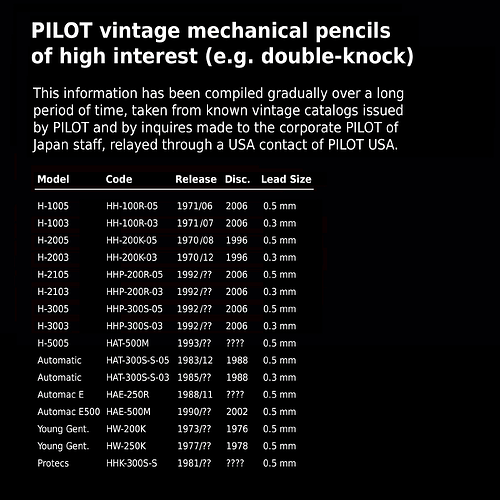

This topic has been an excellent brainstorming workshop/sandbox area. Lots of good info uncovered over time. Near the top I’d put a spreadsheet of sorts to note the dates, which is now riddled with errors. For posterity I’m going to leave it as a document of our journey, but I’ll update that post to include a revision as well.

Here’s a stab at it. Can our veteran double-knock collectors take a look and see if I have any mistakes or omissions? Thanks!

Note that the listing isn’t chronological by release. Since the Hi-mecha series starting with H-1005/H-1003 is by far the most popular and well known, I thought it best to start with those and keep them grouped together… to include the H-5005 at as the last model. And then onto the Automatic/Automac models, and then a few lesser known obscure models. While the Protecs isn’t technically a double-knock, it is 2 step (twist-knock)… and a retractable. So I think it has merit.

EDIT: OK, no comments thus far – I’ve updated the post near the top of the topic (to avoid conveying false information to anyone who might just glance a bit and then move on).

For double-knock Pilots with a cracked body, this isn’t the most elegant of fixes but at least it prevents the pencil from spontaneously disassembling at random intervals:

The fix is quite self-explanatory, I just ordered a bunch of cheap clips on Aliexpress and removed the clip part with wire cutters. The height of the ring can be adjusted for taste as long as it is low enough on the body to prevent the crack from opening.