In the world of mechanical pencils, regulatory standards are the backbone of product quality, safety, and market acceptance. These standards, crafted by international and regional organizations, provide manufacturers with detailed guidelines on everything from design and performance to safety features. This article delves into the key regulatory standards for mechanical pencils, explores why they exist, and highlights their importance in the industry.

Why Regulatory Standards Matter

Regulatory standards serve a vital purpose in the mechanical pencil industry. They exist to protect consumers, ensure consistent product performance, and enable fair trade across borders. Here’s why they’re indispensable:

-

Consumer Safety: Standards address potential hazards, such as the risk of asphyxiation from pencil caps, particularly for products marketed to children. Ventilation requirements for caps, for instance, are designed to prevent tragic accidents.

-

Product Quality: From lead durability to writing smoothness, standards ensure that mechanical pencils perform reliably, meeting consumer expectations for everyday use or specialized tasks like technical drawing.

-

Market Access: Compliance with international and regional standards is often a prerequisite for selling products in different countries. Without adherence, manufacturers risk being shut out of lucrative markets.

These standards benefit manufacturers too. By following them, companies can enhance their reputation, minimize the risk of costly recalls, and avoid legal pitfalls. For consumers, compliance is a signal that a product is trustworthy and safe, fostering confidence and loyalty.

Key International Standards: The ISO Framework

The International Organization for Standardization (ISO) sets globally recognized standards that are critical for manufacturers aiming to compete on an international scale. Below are the primary ISO standards relevant to mechanical pencils:

- ISO 20318-1:2019 - Mechanical Pencils for General Use

- Specifies classification, dimensions, and test methods for everyday mechanical pencils.

- Ensures basic quality and performance for consumer-grade products.

- ISO 9177-1:2016 - Mechanical Pencils for Technical Drawings

- Covers classification, dimensions, and performance requirements for pencils used in precision applications like engineering drawings.

- Guarantees compatibility with technical tools and accuracy needs.

- ISO 20318-2:2019 - Black Leads for General Use

- Defines requirements for lead quality, including hardness grades (e.g., HB, 2B), dimensions, and smoothness.

- Ensures consistent writing performance and lead reliability.

- ISO 9177-2:2022 - Black Leads for Technical Drawings

- Provides classification and dimensional requirements for leads in technical pencils.

- Ensures suitability for professional, precision-based tasks.

- ISO 9177-3:2022 - Bending Strengths of HB Leads

- Specifies bending strength requirements for HB leads in technical drawing pencils.

- Reduces breakage, ensuring durability for detailed work.

- ISO 11540:2021 - Cap Safety for Writing Instruments

- Sets ventilation requirements for caps to prevent choking hazards.

- Critical for safety, especially in products used by children.

- ISO 3098 - Technical Product Documentation (Lettering)

- Includes guidelines for color-coding leads to indicate sizes (e.g., 0.5 mm, 0.7 mm).

- Simplifies consumer selection and standardizes identification.

These ISO standards create a unified framework, allowing manufacturers to produce pencils that meet global expectations for safety, quality, and functionality.

Regional Standards: The Role of JIS in Japan

For manufacturers targeting specific markets like Japan, the Japanese Industrial Standards (JIS) are equally important. While JIS standards often align with ISO, they may include unique requirements tailored to Japanese preferences:

- JIS S6005:2019 - Leads for Mechanical Pencils

- Specifies lead quality, dimensions, and hardness, with potential regional adjustments.

- Ensures products meet the high standards expected by Japanese consumers.

- JIS S6013:2020 - Mechanical Pencils

- Covers classification, dimensions, and performance, often with tighter tolerances than ISO counterparts.

- Reflects Japan’s emphasis on precision and reliability.

Beyond Japan, other regions have their own standards. In the United States, ASTM F963 and CPSIA address toy safety and lead content, while Europe’s EN 71 focuses on similar safety concerns. These regional variations underscore the need for manufacturers to adapt to local regulations.

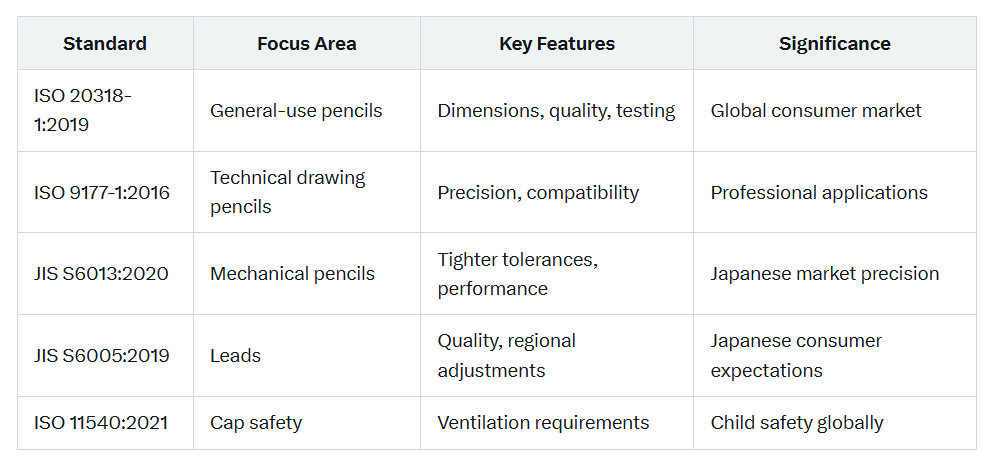

Comparing ISO and JIS Standards

While ISO and JIS standards share common goals, differences exist:

These distinctions highlight why manufacturers must tailor their compliance strategies to specific markets.

The Bigger Picture: Why We Have These Standards

Regulatory standards aren’t arbitrary—they’re rooted in practical needs:

- Safety First: Standards like ISO 11540:2021 emerged frombesides from tragic incidents, ensuring products don’t endanger users.

- Quality Assurance: Standards guarantee that mechanical pencils perform as promised, whether for casual writing or technical precision.

- Global Trade: Uniform standards facilitate cross-border commerce, making it easier for manufacturers to reach international customers.

For manufacturers, compliance isn’t just about meeting requirements—it’s a competitive edge. It builds trust, opens doors to new markets, and protects against reputational damage.

Conclusion

Regulatory standards for mechanical pencils are more than rules to follow—they’re essential for delivering safe, reliable, and high-quality products. From ISO’s global benchmarks to JIS’s regional precision, these standards shape an industry where consumer trust and market success go hand in hand. For manufacturers, embracing compliance is a strategic step toward standing out in a crowded market and ensuring their pencils meet the needs of users worldwide.