I figured it might be useful to have a topic for fielding and answering questions that members might have that they’ve never gotten around to asking (for a variety of reasons).

I’ll start it off.

LEAD SIZE

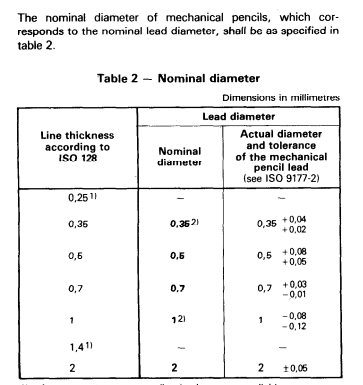

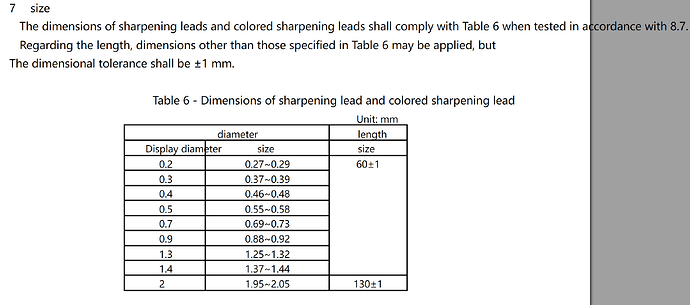

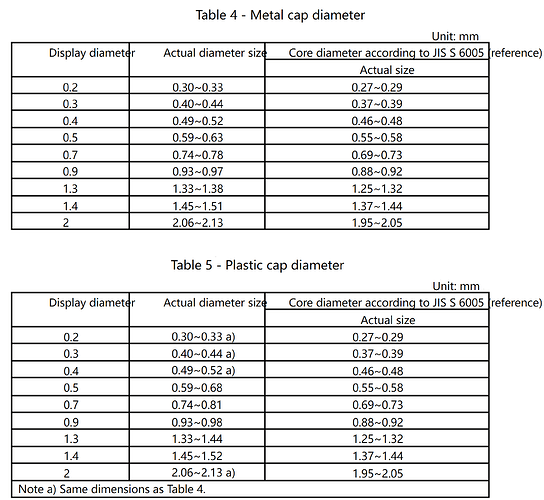

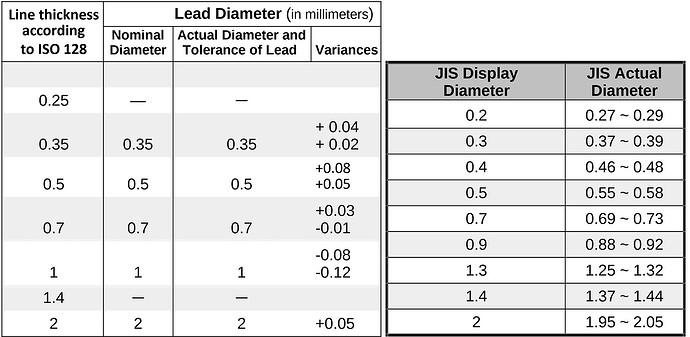

Of course, as we all know the well known mechanical pencil (not holder) common lead sizes are 0.2, 0.3 0.4, 0.5, 0.7, 0.9, and 1.1. But I wonder if these designations are subject to slight variances.

My first question: Is all lead manufactured to the exact same precise diameter as labeled? Meaning, if you had a high precision measuring tool accurate to 0.01 mm, would test measurements of lead from a variety of major lead producing brands all yield the exact same diameter measurement for a given lead size? For example, might some show 0.50mm, but others show 0.49mm or 0.51mm? Or perhaps even wider variances?

Secondly, are all mechanical pencil tips bored out to a 100% precise lead size? Or are there variances to this in the 100th place, possibly as found in lead?

What this leads to is my last question, now that I’ve gotten these two questions on the table. Presuming variances in lead and bore diameter, is it theoretically possible you could have a mechanical pencil in 0.3 mm size that has a bored out diameter of 0.29mm, and you could by chance have 0.3 mm lead that actually measures 0.32 mm, and thus you’d find the lead presents undue friction or might not work at all?

Thanks for your input.