about FC Datagraph: I am quite sure it is not the first 0.9mm (maybe for FC, and maybe for German companies). Thin lead 0.9 should have been introduced in the 1930s, and the Datagraph is post-war (I assume it is somewhat linked to computers, too?)?

that is a really cool pencil @noahf

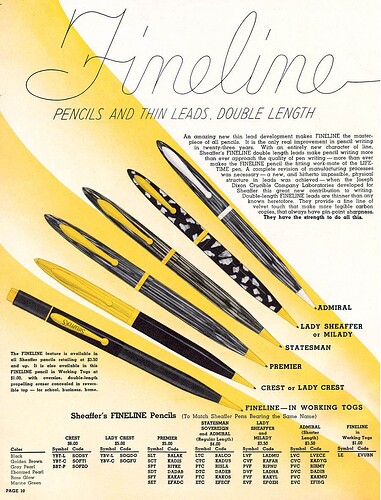

Sheaffer’s Fineline pencil, using 0.9mm lead, was introduced in 1938.

I have an example around the end of 1930s to early 1940s:

Wow, you have some very expensive firsts ![]()

First 0.2mm and sliding sleeve MP: Pentel Orenz

First 0.3mm MP: Pilot H-583

First Kuru Toga: Kuru Toga standard

First Automatic: Orenz Nero

First Double Knock: Graphgear 1000

A completely different “first”: The STAEDTLER Mars micro carbon leads (here the last version).

As far as I know, STAEDTLER were the first to make PVC-free thin leads; old patents indicate that the technology was developed in the early 1960s (I have the impression that there are connections to STAEDTLER’s Duralar and Dynagraph woodcased pencils). They were made in Germany, but some time ago they stopped production and now offer standard leads (i. e. with PVC) from Korea instead.

What’s the advantage of PVC-free leads?

I’m guessing no polymer binding, just clay?

PVC is considered hazardous to health. Chlorine is required during production and dioxins can be produced during incineration. Whether the amount of PVC in the leads is large enough to be problematic is another matter, but the motivation to do without it is certainly understandable.

No, if only clay was used for the leads, they would not be strong enough and would break very easily. If I remember correctly the old patents for the leads which were later used in the Duralar and Dynagraph pencils mention cellulose; I assume that this also applies to the fine leads.

Clays/terracotas become quite strong when you run them through high temperatures, but yeah I guess this doesn’t apply to ~ 0.4mm sticks ![]()

Cellulose is interesting but the process is the same?

Polymers are used because not only it makes stronger leads but also reduces smudging and dirt (possibly inside the manufacturing machines also which is an important factor in the price structure), but I imagine that many manufacturers esp. inside the EU will want or will have to meet certain ecological standards to maintain their licenses, funding or simply position themselves better in the market, which is good.

Yes, of course clay and clay compounds can be very strong but not clay/graphite compounds in such a thin shape.

Unfortunately, I have no idea about the process.

The polymer bond has another advantage: A considerable part of the polymer is carbonised which contributes to blackening.

Ah, yes, the eternal quest for black graphite ![]()

Yes, and the eternal quest for additives which makes the lead even blacker ![]() Some leads contain soot for that purpose but there were times when that was frowned upon.

Some leads contain soot for that purpose but there were times when that was frowned upon.

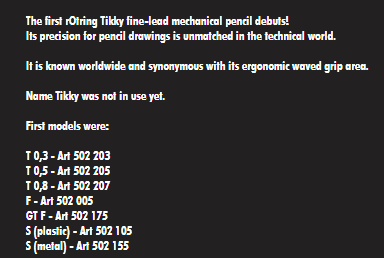

I found another 0.8mm. In 1978 the rOtring T was released. It is listed as a Tikky predecessor. It was initially released in 0.3, 0.5, and 0.8 (model Art 502 207).

I don’t know how long the 0.8 sold but I did some digging and there are 2 versions of the T. V1 was released in 1978. In 1998 they released V2. They discontinued the T in 2008.

https://rotringmuseum.com/history.php

Sadly, that looks like a typo ![]()

The model number would be 502 208 if it was a 0.8 mm. Even the tiny photo there shows 0,7 on the pencil.

I was thinking the same thing -

![]()

I was watching a video on YouTube by Seasar Stationary where he mentioned the Orenz Nero was the first .2 automatic, and implied the first .3 automatic? Maybe something was lost in translation. Can anyone confirm this?

Considering the Orenznero’s automatic mechanism, I’d say that claim is fair, since I’m not aware of any other true automatic-feed 0.2mm pencils…

As far as 0.3 is concerned, the claim seems reasonable, as no other automatic-feed 0.3mm pieces come to mind. (I don’t think the Pilot Automatic actually has an automatic feed, but I don’t have any of these pieces to confirm/deny.)

Part of the confusion could stem from the fact that the word “automatic” has been used for decades in a context we no longer consider to be “automatic.”

I also have no Pilot Automatics but Elton advised that Automatic had the same mechanism as H-5005, so I can only assume 0.3mm auto-advance was featured on the 0.3 Pilot Automatic. I can’t think of earlier auto-advance 0.3mm.